STIHL chain production – how it happens

Take a look behind the scenes at STIHL and discover each production step for our chainsaw chains.

16.06.2025

STIHL chain production | Behind the Scenes

Uncover the quality behind every STIHL saw chain! Did you know? STIHL is the only brand to design, manufacture, and assemble the engine unit, guide bar, and saw chain together. This unique integration ensures seamless compatibility and optimal cutting performance.

Overview: chain production

- STIHL has its own chain factory in Wil, Switzerland

- Saw chains made from special steel are manufactured exclusively for STIHL

- The individual components for saw chains are punched and polished

- Quality control takes place after each step

- We manufacture 70 different types of saw chain

A look inside the chain factory in Wil

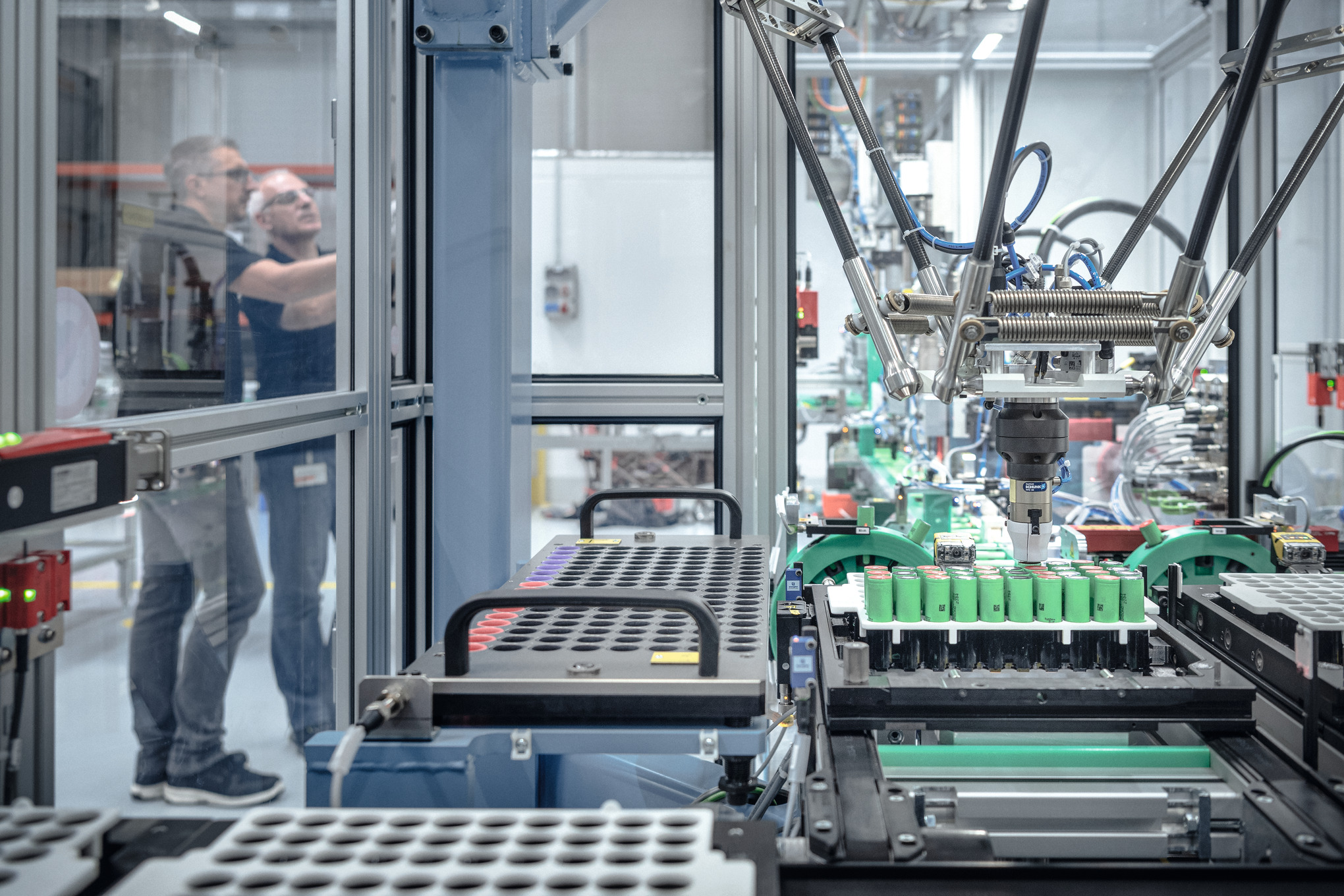

Since the beginning of its 50-year history, quality has been a top priority at the chain plant in Wil. What initially began as a small test operation with six employees has steadily expanded and become gradually more automated. Because chains are required to meet the highest standards, they are continuously tested.

German and Swiss colleagues work together in chain production.

Jochen Ihle, Head of Central Planning, knows the chain factory better than almost anyone. His team procures and develops all the machines and processes needed for chain production.

“Quality is a really key aspect of production for us in the chain factory. Our chains have to meet the highest quality standards.”

(Jochen Ihle, Head of Central Planning)

6-step manufacturing process

What manufacturing steps are required to ensure that our finished saw chains ultimately meet the high quality expectations? Let us guide you through chain production and show you the most important processes.

Our saw chains are made from a special steel which is produced specifically for STIHL. The steel supplier rolls the metal to create long strips, which are then wound onto large spools, known as coils.

The coils are clamped onto the winder, which is part of the punching press. From here the strip unspools and is fed into the die on the punching press.

The individual components for saw chains are then punched with the utmost precision.

During polishing, the fine punching burr created in the punching process is removed or “rounded off”. This ensures that the components have clean edges and run smoothly, and that the finished saw chain later slides easily through wood.

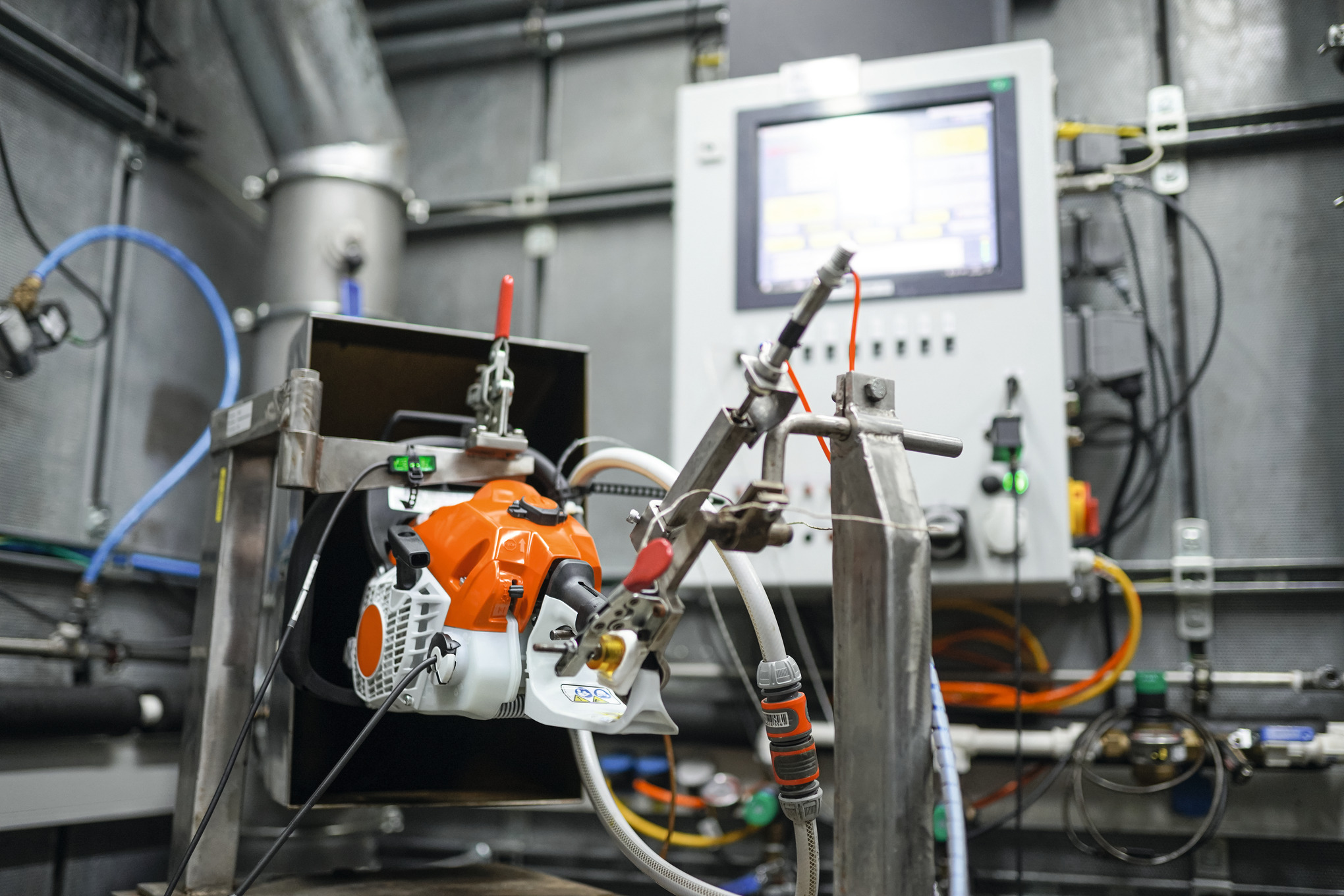

All chain components are hardened – connecting links, drive and cutting teeth as well as rivet bolts. This is achieved by heating components to almost 1000 degrees. The parts are then quenched in a salt bath.

Finally, all individual components are assembled and the rivet bolts installed. This results in a ready-to-use chain that can handle the demands of sawing activity.

Quality control of chains

The quality of the saw chains is checked by STIHL employees after each individual production step. This approach ensures that both the individual components and the chain as a whole are thoroughly inspected.

STIHL is the only manufacturer to develop its own engine unit, saw chain and guide bar in-house, so that they can all be perfectly coordinated together. In-house production and extensive quality control mean we can ensure ideal power tool performance. What’s more, we will continue to develop and refine our manufacturing technology into the future.

Variety of our saw chains

A total of 70 different basic types of saw chains are produced at the Wil site – using special machines that have been developed and produced by STIHL.

The range spans assorted sizes of chain, shapes of cutting teeth and thicknesses of drive link, to suit different guide bars. STIHL offers saw chains for a wide range of performance classes and applications. Some of the main types are briefly listed below:

Discover saw chains and guide bars

All STIHL saw chains and guide bars offer impressively high durability and reliable performance, which is ensured by rigorous quality checks.